Ladmore Burnisher: The Art of Precision in Metalworking

The Ladmore Burnisher is an essential tool in the world of metalworking, jewelry making, and other precision craftsmanship that requires smooth, polished finishes. Designed to create high-quality burnished surfaces on metals like gold, silver, and copper, this tool provides a level of precision and control that enhances the final appearance and durability of the metal. The term “burnishing” refers to the process of polishing or smoothing a surface by rubbing it with a hard, smooth tool, usually under moderate pressure. The Ladmore Burnisher is particularly valued for its ability to achieve a fine, high-shine finish that is both aesthetically pleasing and durable.

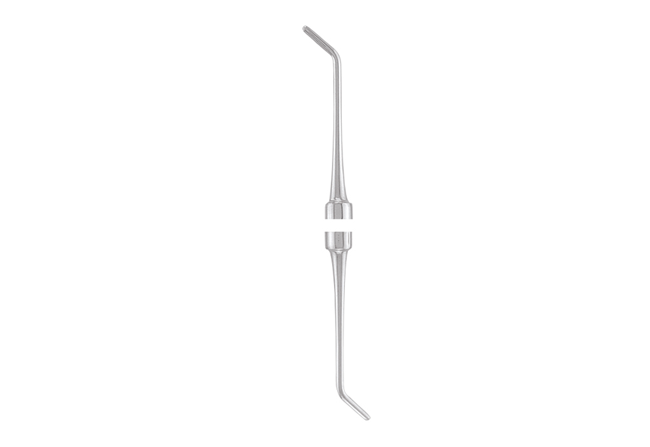

The design of the Ladmore Burnisher is notable for its ergonomic shape, which typically features a sleek, comfortable handle that allows for steady and controlled movements. The burnisher’s working end is made from hardened steel, ensuring that it will not wear down easily, even when used on tough metals. It is available in different shapes, including flat, rounded, and slightly curved heads, which can be used for varying purposes. Whether a jeweler is looking to burnish a ring, a coin, or a decorative metal surface, the Ladmore Burnisher can accommodate a range of tasks, from polishing edges to smoothing out larger flat surfaces.

One of the most important uses of the Ladmore Burnisher is for setting gemstones in jewelry. When setting stones, jewelers need to smooth and compress the metal around the gemstone’s prongs to secure the stone tightly and ensure it is held firmly in place. The burnisher’s precision allows jewelers to delicately burnish around the setting, creating smooth prongs that not only secure the gemstone but also improve the overall visual appeal of the piece. A well-burnished setting has a refined look, with shiny, smooth surfaces that highlight the brilliance of the stone.

Beyond jewelry, the Ladmore Burnisher can also be used in engraving and other fine metalworking processes. It allows artisans to smooth out the rough edges of engraved designs, ensuring that the intricate details of the design remain sharp and well-defined. Burnishing also helps to remove any excess material left after engraving, creating a smooth, polished finish that enhances the clarity and beauty of the design.

The Ladmore Burnisher’s role in metalworking is indispensable because of the durability and shine it imparts to a piece. The burnishing process reduces the appearance of fine scratches and imperfections, leaving the metal with a mirror-like finish. Additionally, it can help prevent tarnishing, as the smooth surface makes it harder for dirt, dust, or other contaminants to adhere to the metal. This, in turn, enhances the longevity of the piece, ensuring that it maintains its polished appearance for years to come.

In summary, the Ladmore Burnisher is a specialized tool that plays a crucial role in the world of metalworking. Its versatility and ability to achieve a smooth, shiny, and durable finish make it an essential tool for jewelers, engravers, and metal artisans. Whether used for polishing, setting gemstones, or refining intricate designs, the Ladmore Burnisher ensures that metal pieces maintain both their functional integrity and their visual appeal.

Reviews

There are no reviews yet.