Need help? Call us:

+91-9310354377

- ACCESSORIES

- DIAGNOSTICS

- ENDODONTIC AND CONSERVATIVE DENTISTRY

- AMALGAM CARRIER

- ART INSTRUMENTS

- BURNISHER

- CARVER

- CHISELS & HOE

- COMPOSITE INSTRUMENTS ANTERIOR & POSTERIOR BLACK

- COMPOSITE INSTRUMENTS ANTERIOR & POSTERIOR BLUE

- COMPOSITE INSTRUMENTS GOLD FLEXI THIN

- COMPOSITE INSTRUMENTS SILICON BLACK/BLUE

- COMPOSITE INSTRUMENTS TITANIUM BLUE

- COMPOSITE INSTRUMENTS TITANIUM GOLD

- ENDO INSTRUMENT KITS

- MARGIN TRIMMER

- MATRIX RETAINER

- PLACEMENT INSTRUMENTS

- PLASTIC FILLING INSTRUMENTS

- PLUGGER/CONDENSERS

- RCT PLUGGER

- RCT SPREADERS & HEAT CARRIERS

- ROOT FRAGMENT STEIGLITZ

- RUBBER DAM CLAMP

- RUBBER DAM FORCEP AND PUNCH

- RUBBER DAM FRAME

- SPOON EXCAVATOR

- IMPLANTOLOGY

- INSTRUMENTS MANAGEMENT SYSTEM

- LUXATIP

- MICRO SURGERY

- NEW ARRIVAL

- ORAL AND MAXILLOFACIAL SURGERY

- ORAL SURGERY

- ALLIS & TISSUE FORCEPS

- ASSORTED SURGICAL KITS

- BONE CHISEL & MALLETS

- BONE RONGEURS

- CHEEK RETRACTORS & TISSUE RETRACTORS

- DENTAL SYRINGE

- EXTRACTION FORCEPS AMERICAN PATTERN

- EXTRACTION FORCEPS ATRAUMATIC

- EXTRACTION FORCEPS ERGONOMIC

- EXTRACTION FORCEPS PEDO PREMIUM

- EXTRACTION FORCEPS PEDO STANDARD

- EXTRACTION FORCEPS PREMIUM

- EXTRACTION FORCEPS PREMIUM #BLACK

- EXTRACTION FORCEPS SECURE

- EXTRACTION FORCEPS STANDARD

- HEMOSTATS & NEEDLE HOLDERS

- METAL & FRAZIER SUCTION TUBE

- NEW CLINIC SET UP KITS

- PERIOSTEAL ELEVATOR & BONE FILE

- PROXITIP - LUXATING HYBRIDS

- RETRACTOR

- ROOT ELEVATOR LINDO LEVIAN

- ROOT ELEVATOR PREMIUM

- ROOT ELEVATOR STANDARD

- SCALPEL HANDLES

- SCISSORS

- TOWEL CLAMPS, DRESSING & STERLISING FORCEPS

- TUNGSTEN CARBIDE SCISSOR & NEEDLE HOLDER

- ORTHODONTICS

- PERIODONTAL

- COLUMBIA CURETTES

- CORN SUTURE PLIER & POCKET MARKER

- GRACEY CURETTE

- GRACEY CURETTE COLOR CODED

- LANGER CURTTES

- MC CALL CURETTES

- PERIO INSTRUMENT KITS

- PERIO PROBES

- PERIODONTAL CHISEL

- PERIODONTAL FILES

- PERIODONTAL KNIVES

- PERIODONTAL SCALERS

- PERIOTOMES

- SUB GINGIVAL SCALER

- SUPRA GINGIVAL SCALER

- SURGICAL CURETTE & BONE CURETTE

- TISSUE NIPPER & BLADE HOLDER

- TUNNELLING KNIVES

- VISTA TUNNELING PROCEDURE

- PROSTHODONTIC

- ANTERIOR AND POSTERIOR & ADJUSTABLE

- ARTICULATING PAPER HOLDER & CROWN HOLDING FORCEP

- ARTICULATOR, PUTTY CUTTER & PLASTER SHEARS

- CALIPER IWANSON

- CEMENT SPATULA & HIDEMANN SPATULA

- CROWN REMOVER

- GINGIVAL CORD PACKER

- IMPRESSION TRAY DENTULOUS NON-PERFORATED

- IMPRESSION TRAY DENTULOUS PERFORATED

- IMPRESSION TRAY DENTULOUS PERFORATED PEDO

- IMPRESSION TRAY EDENTULOUS NON-PERFORATED

- IMPRESSION TRAY EDENTULOUS PERFORATED

- IMPRESSION TRAY HALF

- PKT CARVERS

- PKT CARVERS COLOR CODED

- PROSTHODONTIC INSTRUMENT KITS

- WAX & MODELLING CARVER

- WAX KNIVES & SPATULA

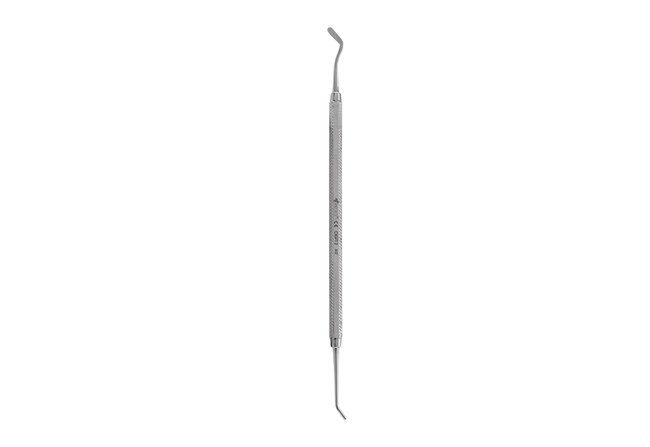

PLASTIC FILLING INSTRUMENT #PFGFT2

PLASTIC FILLING INSTRUMENT #PFGFT2

₹300.00 Original price was: ₹300.00.₹240.00Current price is: ₹240.00.

Plastic Filling Instrument #PFGFT2: A Comprehensive Overview

The Plastic Filling Instrument #PFGFT2 is an advanced tool designed to meet the increasing demand for precision in plastic repair and filling applications. This instrument is typically used in various industries, including automotive, manufacturing, and construction, where the need for flawless finishes in plastic repairs and modifications is crucial. The PFGFT2 is engineered to provide users with an efficient and effective solution for filling gaps, cracks, and surface imperfections in plastic materials, ensuring a durable and aesthetically pleasing result.

Key Features and Functionality

One of the standout features of the PFGFT2 is its ergonomic design, which makes it comfortable to use for extended periods without causing strain. The handle is crafted from a durable, lightweight material, allowing for better control and precision. This is particularly important when working with delicate plastic surfaces that require fine adjustments. Additionally, the tool’s compact size makes it highly portable and easy to store, making it a versatile choice for professionals on the go.

The filling mechanism of the PFGFT2 is designed to provide smooth, consistent application. It is equipped with a specialized nozzle that allows for controlled dispensing of the filling material. This ensures that the filler is applied evenly across the damaged area, reducing waste and ensuring a seamless finish. The tool’s high-efficiency system enables users to complete jobs faster while maintaining the desired quality. It is also compatible with a wide range of fillers, including epoxy resins, polyester compounds, and other plastic repair substances.

Applications

The PFGFT2 is widely used for plastic repairs in various industries. In the automotive sector, it is particularly useful for repairing damaged bumpers, dashboards, and trim components. The tool’s precision ensures that the filler is applied in a manner that matches the texture and finish of the original plastic surface, making the repair virtually undetectable.

In construction, the PFGFT2 is utilized for filling cracks and gaps in plastic pipes, ducts, and fittings. Its ability to create a smooth, durable finish ensures that the repaired areas are both functional and aesthetically pleasing. The tool is also useful in the manufacturing of plastic products, where it can be used for quality control purposes to ensure that products meet industry standards.

Benefits of Using the PFGFT2

The primary advantage of using the PFGFT2 is its ability to provide a precise and professional finish. Unlike traditional methods of plastic repair, the PFGFT2 minimizes the likelihood of uneven surfaces or excess filler, which can compromise the quality of the repair. The consistent flow of filling material ensures that repairs are strong and reliable, offering long-lasting solutions for plastic surface restoration.

Moreover, the PFGFT2 reduces the time and effort required for plastic repairs. By providing a more efficient application process, it allows users to complete repairs more quickly, improving overall productivity. The tool’s versatility also extends its usefulness to a wide range of plastic materials, making it an essential tool for any professional working with plastic.

Conclusion

In conclusion, the Plastic Filling Instrument #PFGFT2 is an indispensable tool for professionals in industries requiring plastic repair and filling. Its ergonomic design, efficient filling mechanism, and compatibility with various materials make it an ideal choice for achieving high-quality repairs. Whether in automotive, construction, or manufacturing, the PFGFT2 helps users achieve professional results with ease and precision.

Recently Viewed Items

ALBRECHT FORCEP MOLAR NO. 2

ALBRECHT FORCEP PREMOLAR NO. 1

LOWER MOLAR No. 73

LOWER MOLAR No. 22S

LOWER MOLAR No. 86

LOWER MOLAR No. 86A

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.